Tungsten Carbide Carbide Sphere

Sifo

Canebide ilkaha laf-dhabarka ayaa si weyn loogu isticmaalaa qalabka barafka ee qoditaanka shidaalka iyo ka saarida barafka. Intaas waxaa sii dheer, ilkaha carbiska ee loo yaqaan 'Clebide' ayaa sidoo kale si wanaagsan loogu isticmaalaa goynta aaladaha iyo mashiinnada macdanta, dayactirka wadada iyo aaladaha qodista dhuxusha. Ilkaha kubadaha kubada cagta ee loo yaqaan 'carbide' ee lagu isticmaalo miinooyinka waxaa badanaa loo isticmaalaa aalado ku jira dhul-gariir, macdanta, tunneelka iyo dhismayaasha madaniga ah.

Isticmaal

Badhanka loo yaqaan 'Carbide Carbide' oo loo yaqaan 'Carbide' oo loo yaqaan 'Carbide' Marka loo eego mashiinnada qoditaanka ee kaladuwan, sida xargaha saqafka, aaladaha Dt-ka, aaladaha qoditaanka juqraafiga, booska loo yaqaan 'carbide', booska ugu sarreeya ee booska, booska kubada z-coin. Deganaansho iyo tikniyoolajiyad sare ayaa xaqiijisan in tayada sare ee badeecadeena, ilkaha carbiska ee loo yaqaan 'carbide ilkaha' waxaa badanaa loo isticmaalaa aalado qodista shaashadda, qalabka mashiinka mashiinka macdanta iyo aaladaha dayactirka wadada ee barafka iyo nadiifinta wadada. Ilkaha kubadaha kubadaha ee loo yaqaan 'Carbide' oo loo yaqaan 'carbide' oo loo yaqaan 'carbide'. Intaas waxaa sii dheer, waxaa sidoo kale loo istcimaalaa waxoogaa ku habboon oo loogu talagalay gawaarida dhagaxa weyn ee dhagaxa weyn ama daloolka qoto dheer.

Astaamaha

Carbide-ka ayaa ah waxyaabaha ugu fiican ee lagu soo saaro ilkaha kubadaha kubadaha loo yaqaan 'carbide' oo loo adeegsado warshadaha qoditaanka ee 'DTMER Diser'.

Badhanka Carbide waxaa si weyn loogu isticmaalaa mindhicirka, goynta iyo goynta adag awgeed. Waxaa sidoo kale loo isticmaali karaa qashin qod culus.

Heer u qaybin

| Heer u qaybin | Cucidg / cm3 | Trs mpa | AdkaynHaa | Isticmaal |

| Cr4c | 15.10 | 1800 | 90.0 | Inta badan loo isticmaalo goynta aaladaha adag iyo jilicsan ee saamaynta saameynta. |

| Cr6 | 14.95 | 1900 | 90.5 | Waxaa loo istcimaalaa sida dhuxusha korantada korantada, dhuxusha xulashada, batroolka shidaalka iyo qaniinyada kubadaha kubadaha. |

| CR8 | 14.80 | 2200 | 89.5 | Waxaa loo isticmaalay sidii tababbaryo cakiran, Dalladaha Korontada Korontada, Dhuxul Dhuxul, Pital Pital, Petroleum Cone-ga Cones iyo Thrown Free Plepples. |

| CR8C | 14.80 | 2400 | 88.5 | Badanaa loo isticmaalay sidii ilig kubad oo dhexdhexaad ah iyo saameyn yar oo saameyn yar iyo sida u qaadaya baadiyaha sahaminta sicirka. |

| CR11C | 14.40 | 2700 | 86.5 | Intooda badan waxaa loo isticmaalaa saameynta tababbarka iyo tababbarka korantada si loo jaro kubada cagta ee walxaha adag. |

| CR13C | 14.2 | 2850 | 86.5 | Badanaa loo isticmaalay goynta ilkaha kubada cagta ee agabyada dhexdhexaadka ah iyo waxyaabaha adag ee adag ee tacabka saameynta wareejinta. |

| CR15C | 14.0 | 3000 | 85.5 | Waxaa loo isticmaalaa aaladda saliida ee saliida iyo qalabka jilicsan ee jilicsan iyo kuwa dhexdhexaadka ah. |

Weynaan

OEM waa la aqbalay.

Cabirka caadiga ah ee batoonka tungsten ee batoonka ee ku hoos yaal:

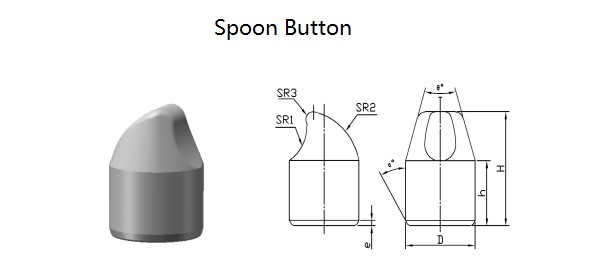

| Teeb ku qorid | Cabbir (mm) | ||||||||

| D | H | h | ° | SR1 | SR2 | SR3 | ° | e | |

| S1015 | 10.25 | 15 | 9.8 | 50 | 12 | 20 | 3 | 18 | 1.2 |

| S1116 | 11.3 | 16.5 | 10.2 | 50 | 15 | 24 | 3 | 18 | 1.2 |

| S1218 | 12.35 | 18 | 11 | 36 | 20 | 25 | 2.5 | 18 | 1.5 |

| S1319 | 13.35 | 19 | 12 | 50 | 15 | 20 | 3 | 18 | 1.5 |

| S1421 | 14.35 | 21 | 12.5 | 40 | 12 | 25 | 3 | 18 | 1.8 |

| S1521 | 15.35 | 21 | 12 | 50 | 20 | 30 | 3 | 18 | 1.8 |

| S1624 | 16.35 | 24 | 13 | 30 | 15 | 20 | 3 | 18 | 2 |

| S1827 | 18.25 | 27 | 14.5 | 30 | 18 | 20 | 3 | 18 | 2 |

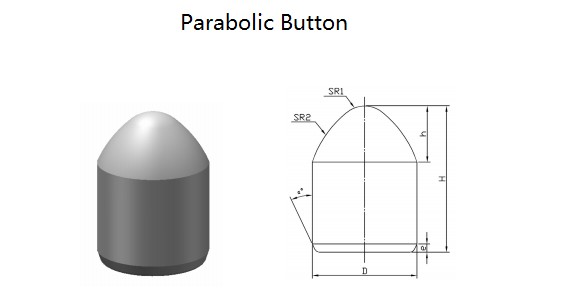

| Teeb ku qorid | Cabbir (mm) | |||||||

| D | H | SR1 | SR2 | h | ° | β ° | e | |

| D0711 | 7.25 | 11 | 1.9 | 8.7 | 3.9 | 20 | 25 | 1.6 |

| D0812 | 8.25 | 12 | 2.5 | 9 | 4.5 | 20 | 25 | 1.6 |

| D0913 | 9.25 | 13 | 2.5 | 11 | 5 | 20 | 25 | 1.8 |

| D1015 | 10.25 | 15 | 3.2 | 11.8 | 5 | 20 | 25 | 1.8 |

| D1117 | 11.3 | 17 | 3 | 13.5 | 6 | 20 | 25 | 1.8 |

| D1218 | 12.35 | 18 | 3 | 12 | 6.5 | 20 | 20 | 2 |

| D1319 | 13.35 | 19 | 3.5 | 13.5 | 7.1 | 20 | 20 | 2 |

| D1420 | 14.35 | 20 | 4.2 | 13 | 8 | 20 | 20 | 2 |

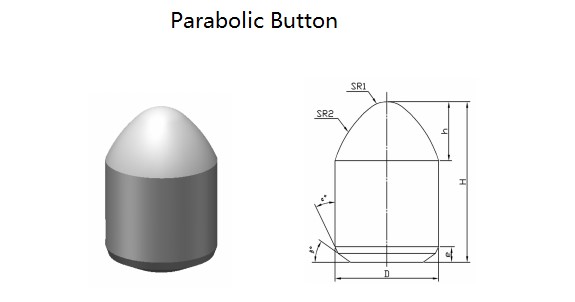

| Teeb ku qorid | Cabbir (mm) | ||||||

| D | H | SR1 | SR2 | h | ° | e | |

| D0711a | 7.25 | 11.0 | 1.9 | 8.7 | 3.9 | 18 | 1 |

| D0812a | 8.25 | 12.0 | 2.5 | 9 | 4.5 | 18 | 1 |

| D0913a | 9.25 | 13.0 | 2.5 | 11 | 5 | 18 | 1 |

| D1015a | 10.25 | 15.0 | 3.2 | 11.8 | 5 | 18 | 1.2 |

| D1117A | 11.3 | 17.0 | 3 | 13.5 | 6 | 18 | 1.2 |

| D1218a | 12.35 | 18.0 | 3 | 12 | 6.5 | 18 | 1.5 |

| D1319a | 13.35 | 19.0 | 3.5 | 13.5 | 7.1 | 18 | 1.5 |

| D1420a | 14.35 | 20.0 | 4.2 | 13 | 8 | 18 | 8 |

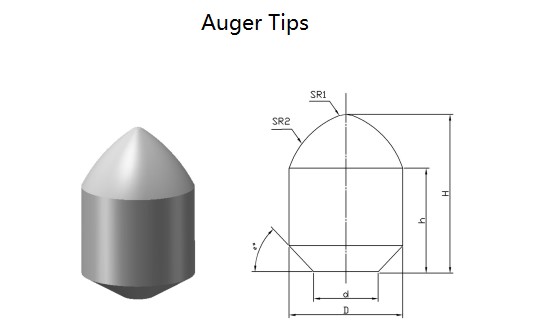

| Teeb ku qorid | Cabbir (mm) | |||||

| D | d | H | h | SR1 | SR2 | |

| Jm1222 | 12 | 3.0 | 22 | 15 | 1.5 | 26 |

| Jm1425 | 14 | 4.0 | 25 | 17 | 1.5 | 26 |

| Jm1625 | 16 | 5.0 | 25 | 16 | 1.5 | 26 |

| Jm1828 | 18 | 5.0 | 28 | 18 | 1.5 | 26 |

| Jm2428 | 24 | 10.1 | 28 | 16 | 2 | 36 |

| Jm2534 | 25 | 18.0 | 34 | 20 | - | 25 |

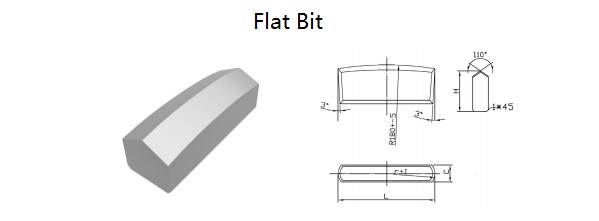

| Teeb ku qorid | Cabbir (mm) | |||||

| L | H | C | r | |||

| A | B | C | ||||

| K026 | 26 | 18.0 | 15 | 12.5 | 8 | 13 |

| K028 | 28 | 18.0 | 15 | 12.5 | 8 | 14 |

| K030 | 30 | 18.0 | 15 | 12.5 | 8 | 15 |

| K032 | 32 | 18.0 | 15 | 12.5 | 8 | 16 |

| K034 | 34 | 18.0 | 15 | 12.5 | 8 | 17 |

| K036 | 36 | 18.0 | 15 | 12.5 | 10 | 18 |

| K038 | 38 | 18.0 | 15 | 12.5 | 10 | 19 |

| K040 | 40 | 18.0 | 15 | 12.5 | 10 | 20 |

| K042 | 42 | 18.0 | 15 | 12.5 | 10 | 21 |

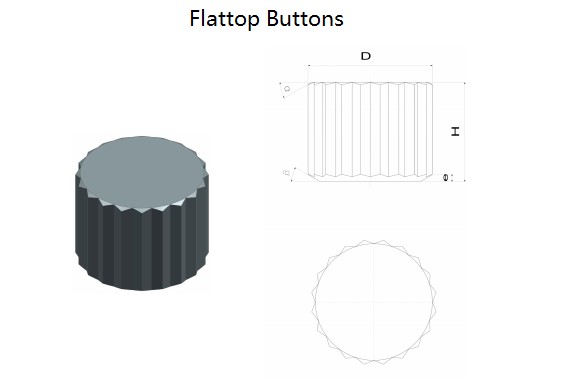

| Teeb ku qorid | Cabbir (mm) | ||||

| D | H | t | ° | e | |

| MH0806 | 8 | 6.0 | 0.5 | 25 | 1.1 |

| Mh1008 | 10 | 8.0 | 0.5 | 25 | 1.9 |

| Mh1206 | 12 | 6.0 | 0.5 | 25 | 1.9 |

| Mh1208 | 12 | 8.0 | 0.5 | 25 | 2.5 |

| Mh1410 | 14 | 10.0 | 0.5 | 25 | 2.5 |

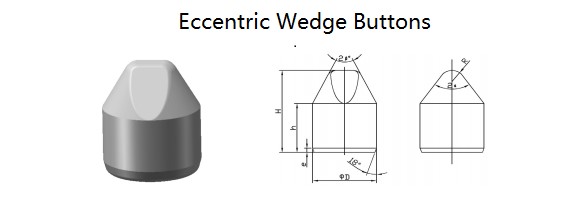

| Teeb ku qorid | Cabbir (mm) | |||||||

| D | H | h | R | r | ° | β ° | e | |

| X0810 | 8 | 10 | 6.5 | 2 | 1.8 | 45 | 22.5 | 1.5 |

| X1011 | 10 | 11 | 7 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1013 | 10 | 13 | 9 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1115 | 11 | 15 | 8 | 2.8 | 2.5 | 22.5 | 22.5 | 1.5 |

| X1215 | 12 | 15 | 9 | 3 | 2.5 | 45 | 22.5 | 1.5 |

| X1217 | 12 | 17 | 10.5 | 3.5 | 3 | 35 | 20 | 1.5 |

| X1418 | 14 | 18 | 10 | 3.5 | 3 | 45 | 22.5 | 1.5 |

| X1420 | 14 | 20 | 11 | 2.7 | 3 | 35 | 22.5 | 1.5 |

| X1520 | 15 | 20 | 12 | 3 | 3 | 40 | 22.5 | 1.5 |

| X1621 | 16 | 21 | 11 | 2.6 | 3 | 35 | 22.5 | 2 |

| X1623 | 16 | 23 | 12 | 3 | 3.5 | 30 | 18 | 2 |

| X1721 | 17 | 21 | 13 | 4 | 3.5 | 40 | 22.5 | 2 |

| X1724 | 17 | 24 | 13 | 3.5 | 3.5 | 30 | 22.5 | 2 |

| X1929 | 19 | 29 | 17 | 4 | 3 | 30 | 15 | 2 |

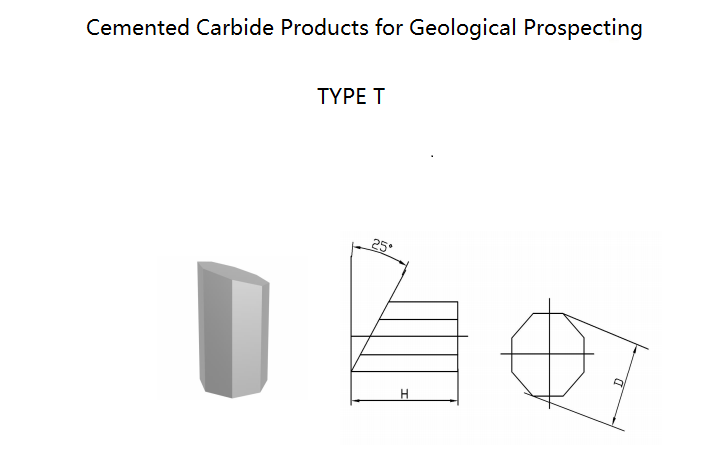

| Teeb ku qorid | Cabbir (mm) | |

| D | H | |

| T105 | 5 | 10 |

| T106 | 7 | 10 |

| T107 | 7 | 15 |

| T109 | 9 | 12 |

| T110 | 10 | 16 |

Faa'iidooyinkayaga

Badhanka loo yaqaan 'Carbide Carbide' ee loo yaqaan '' '' Nolosha aan shiidan ee waxoogaa waa 5-6 jeer illaa iyo inta ka mid ah isla dhexroor isla dhexroor, kaas oo faa'iido u leh badbaadinta saacadaha kaabayaasha ah, yareynta shaqada gacanta iyo xawaareynta xawaaraha injineerka.

Si aad u hesho faahfaahin dheeraad ah, soo dhawow inaad nala soo xiriirto wakhti kasta!

Qalabka wax soo saarka

Shiidi qoyan

Buufin qalajinta

Saxaafad

Taabo TPA

Semi-Press

Sinta sinta

Qalabka wax ka qabashada

Qoditaan

Goynta goynta

Shiidan toosan

Universal Criding

Diyaaradda diyaaradda

Mashiinka dhagaxa cnc

Aaladda kormeerka

Mitirka adag

Dhismo loogu magacaabi karo

Cabbirka walxaha qubiscatic

Qalabka magnetic magnetic magnetic

Metrographic Microscope-ka