Qaybaha MWD & LWD

Sifo

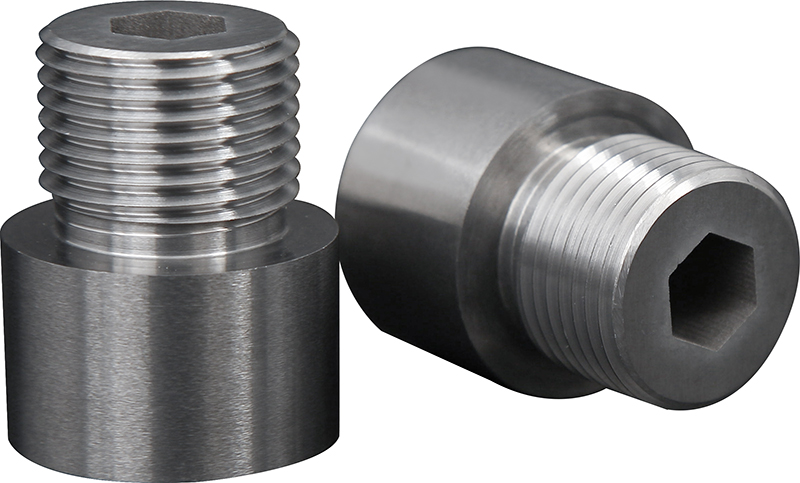

-Ga / -daTungsten Carbide Carbide dhammaadLoogu talagalay MWD iyo LWD waxaa badanaa loo isticmaalaa shaqada daadashada, slurry hubinta, weecinta qulqulka, iyo u dirista cadaadiska sturry iyo macluumaad kale oo lagula soo celiyo garaaca wadnaha. The Tungsten Carbide Main Valve Core waa mid ka mid ah iyaga oo loo adeegsaday MWD iyo LWD. Faahfaahinta kala duwan ee xarkaha weyn ee loo yaqaan 'valve' ee loo yaqaan 'valve'

Warshaddayada annaga oo adeegsanayna tayo-tayo sare oo Shiinaha ah oo tayo sare leh si loo soo saaro Tilmaanta Poppet-ka oo hubiya caabbinta caabbinta si loo yareeyo cufnaanta tikniyoolajiyadda si ay u yareeyaan cufnaanta labiska. Hagaajinta xoogga foosha iyo nolosha daalka ee carbide.

Hawlahayaga ENO-ga ee Sare ee CNC waxay xaqiijineysaa in dhul walba oo kale lagu soo saaray si sax ah oo ugu weyn. Farsamaynta farsamada ee kombiyuutarka ee kombiyuutarka ayaa dammaanad qaadaya cabirro joogto ah, oo hagaagsan, oo u dulqaadasho adag, taasoo dhalisay in wax soo saar ay sifiican ugu hoggaansamaan macaamiisha.

Darada

Dhamaadka Poppet ayaa laga sameeyaytUngsten CarbideQalabka Nidaamka wax soo saarka ee sifiican u xaqiijinayo sax ahaanta ugu sareysa iyo joogtaynta darida. Heerkan saxsanaanta, waad ku kalsoonaan kartaa in popt-ka kasta uu si khaldan ugu habboonaan kara qalabkaaga qodista.

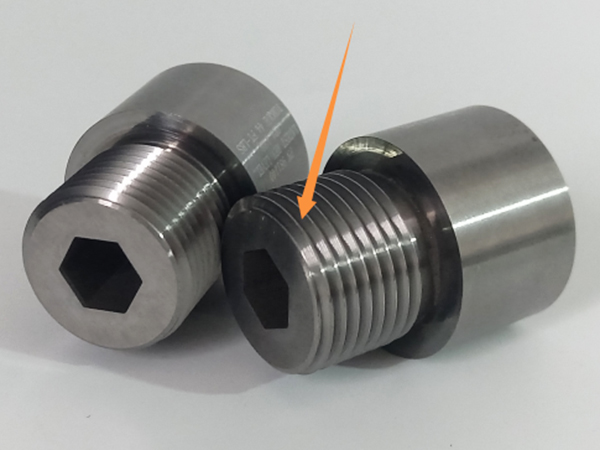

Laser oo lagu calaamadeeyay xaqiijinta cabirka ee degdegga ah iyo raadinta.

Faahfaahinta

Carbide poppet dhamaadka

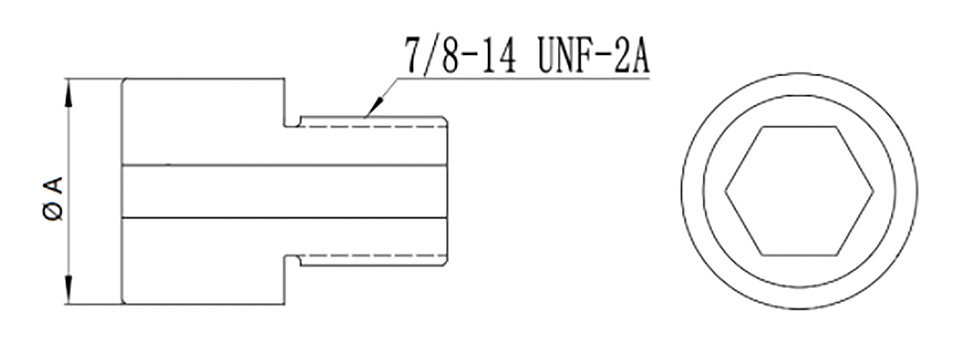

| Wax | Cabbirka OD | Dun |

| 981213 | Ø.086 '' | 7/8-14 aan lahayn-2a |

| 981214 | Ø.040 '' ' | 7/8-14 aan lahayn-2a |

| 981140 | Ø.122 '' '' | 7/8-14 aan lahayn-2a |

Iyada oo xulashooyin kaladuwan oo kala duwan oo la heli karo, oo u dhexeeya OD1.086 '', 1.040 '', '' '' ', waxaan sidoo kale aqbali karnaa in loo dhiso si waafaqsan shuruudaha macaamiisha. Iyo inbadan, waxaad ka heli kartaa taam ahaanshaha kaamil ah ee shuruudaha qalabka qoditaanka.

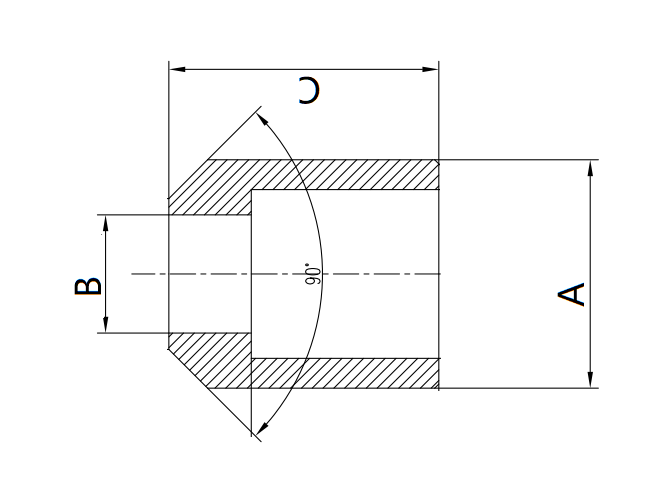

Tilmaamaha 'Carbide Poppet' P360

| लaa | ØB | Øc |

| 1.04 '' '' | 0.57 '' '' | 1.30 '' |

| 1.086 '' | 0.57 '' '' | 1.30 '' |

| 1.125 '' '' ' | 0.57 '' '' | 1.30 '' |

| 1.16 '' | 0.57 '' '' | 1.30 '' |

Carbide poppet qaar ka mid ah fasalada sida soo socota:

| Dhibcaha | Guryaha jireed | Arjiga ugu weyn iyo astaamaha | ||

| Adkayn | Cucid | Tres | ||

| Haa | g / cm3 | N / mm2 | ||

| CR35 | 88.5-89.5 | 14.30-14.50 | ≥2800 | Waxay ku habboon tahay in la soo saaro gacmo gacmeedyo ubaxyo iyo waxyaabo aan lahayn dhibaato weyn iyo caabbinta wanaagsan, |

| Cr06n | 90.2-91.2 | 14.80-15.00 | ≥2560 | Waxay ku habboon tahay in la soo saaro gacmo gacmeedyo iyo googoyin loo isticmaalo warshadaha saliida & gaaska sababtuna tahay caabbinta naxdinta leh iyo caabbinta, |

Faa'iidooyinkayaga

● Gaaban oo waqti gaarsiinta

● Cabbirka saxda ah ee la xakameeyo

● caabbinta wanaagsan

Adeegyadeena

Shahaadada fasalka

Childs Chicil iyo tijaabada sheyga iyo oggolaanshaha

● Falanqaynta muunado ayaa la heli karaa

Sidoo kale waad jeclaan kartaa

TALOOYINKA POPTET

Giraanta xoojiye

Iftiin Orifice-ka

Si joogto ah 350/650 puls orifice

Qalabka wax soo saarka

Shiidi qoyan

Buufin qalajinta

Saxaafad

Taabo TPA

Semi-Press

Sinta sinta

Qalabka wax ka qabashada

Qoditaan

Goynta goynta

Shiidan toosan

Universal Criding

Diyaaradda diyaaradda

Mashiinka dhagaxa cnc

Aaladda kormeerka

Mitirka adag

Dhismo loogu magacaabi karo

Cabbirka walxaha qubiscatic

Qalabka magnetic magnetic magnetic

Metrographic Microscope-ka